E-Wood, energy from wood waste

E-Wood will be able to process 180,000 tons of wood waste per year.

This concerns wood waste that is not suitable for material recycling, such as treated wood waste or wood-based materials from composting facilities for example. Though no longer recyclable to make new wood products, it can be usefully applied as raw material for the production of green energy.

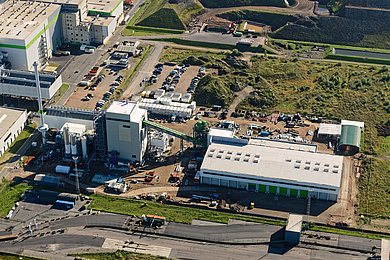

Storage and processing takes place in a covered area. The wood waste is thermally processed in a fluidised bed installation. The facility is equipped with intensive flue gas cleaning.

This cogeneration facility produces both heat and current. E-Wood has a thermal capacity (power capacity) of 71MW. Using a turbine, up to 20MW of electricity can be supplied.

Green energy - a sustainable solution

E-Wood supplies green energy by processing a renewable source. Wood waste is after all a biological resource. The emissions avoided by E-Wood can be compared to the CO2 emissions avoided by about 45 wind turbines. E-Wood produces heat and electricity from a renewable source. In this way we avoid energy production from fossil fuels.

Doel Energy Hub

Indaver and Veolia have been exploiting three fluidised bed installations for the sustainable and safe processing of non-hazardous waste and sludge at Indaver’s Doel site since as long ago as 2006. At the same site Indaver also operates three grate incinerators for processing domestic waste.

E-Wood is thus integrated at a site where existing facilities for the production of energy are already available, such as three turbines (total 85 MW) and a steam pipe for 160 MW high pressure process steam.

These combustion processes supply energy in the form of steam and electricity. The steam is supplied directly through the Ecluse steam network to businesses in the Waasland port. This enables them to disconnect their gas-fired boilers and save on the use of fossil fuels. The electricity is fed into Elia’s high voltage grid.

This offers opportunities for the further development of economic activities in the port. E-Wood reinforces the energy cluster at the Indaver site in Doel and provides assurance of continuous provision of power. Furthermore, the green current will appreciably improve the ecological footprint of the companies that use it.

Contribution to the (Flemish) renewable energy objectives

With its “green deal”, the European Commission has established some ambitious objectives. By 2030 the share of energy from renewable sources in the energy mix must be at least 30%. Flanders needs green energy to attain these climate targets.

With the new E-Wood facility for processing non-recyclable wood waste, Flanders comes a step close to attaining these goals.

Sustainable waste management in the circular economy

In a circular economy, materials are re-used as much and as efficiently as possible. Companies such as Indaver and Veolia, active players in sustainable waste management and both shareholders in E-Wood, play an essential role in this.

Nicolas Germond, CEO Veolia:“By converting non-recyclable wood waste into energy locally, we avoid consuming fossil fuels. And in this way we support natural resources, promote local energy production circuits and thus the circular economy. With E-Wood we can further accelerate the ecological transformation. That’s what it’s all about for Veolia.”

Paul De Bruycker, CEO Indaver: “As Indaver we are constantly focused on creating value by reclaiming materials or energy. For us, waste is not an end product. With E-Wood we get green energy back from waste wood that is not suitable for recycling. It’s an example of industry’s commitment to working together to attain the climate goals.”